Essential for Car Door Panel Upgrades: Ultrasonic Plastic Welding Machine – Restore OEM Quality After Ambient Light Modifications!

Essential for Car Door Panel Upgrades: Ultrasonic Plastic Welding Machine – Restore OEM Quality After Ambient Light Modifications!

Blog Article

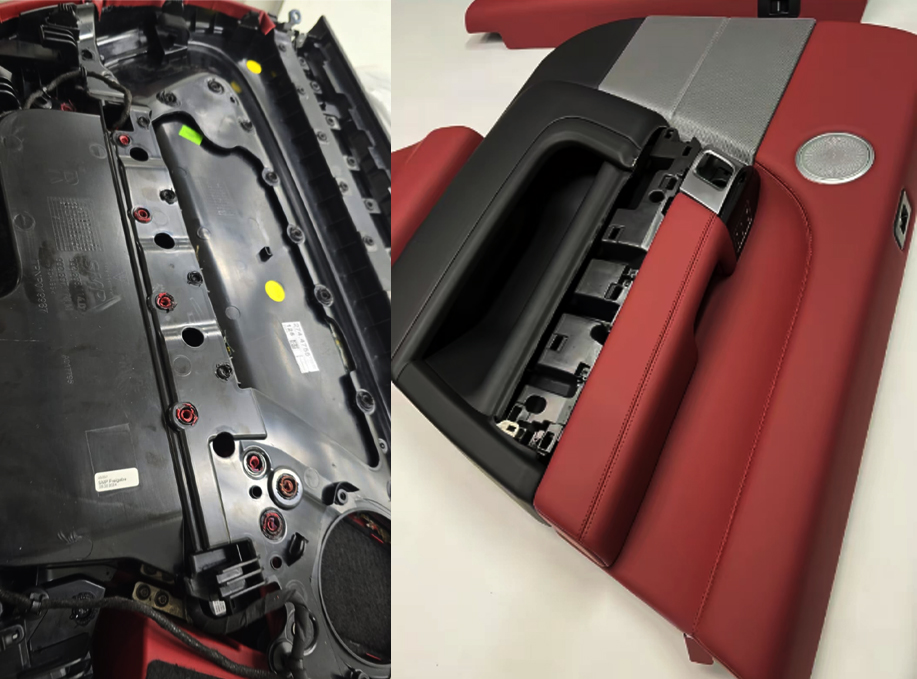

During modification, removing the door panel is necessary to access internal wiring or install LED strips. Unfortunately, original plastic rivets or weld points are often damaged during this process. Traditional reattachment methods like screws or glue can compromise the finish and structural integrity.

With ultrasonic plastic welding, you can quickly and cleanly re-weld plastic parts at the original joint points. The result is a seamless, strong bond — just like the factory finish.

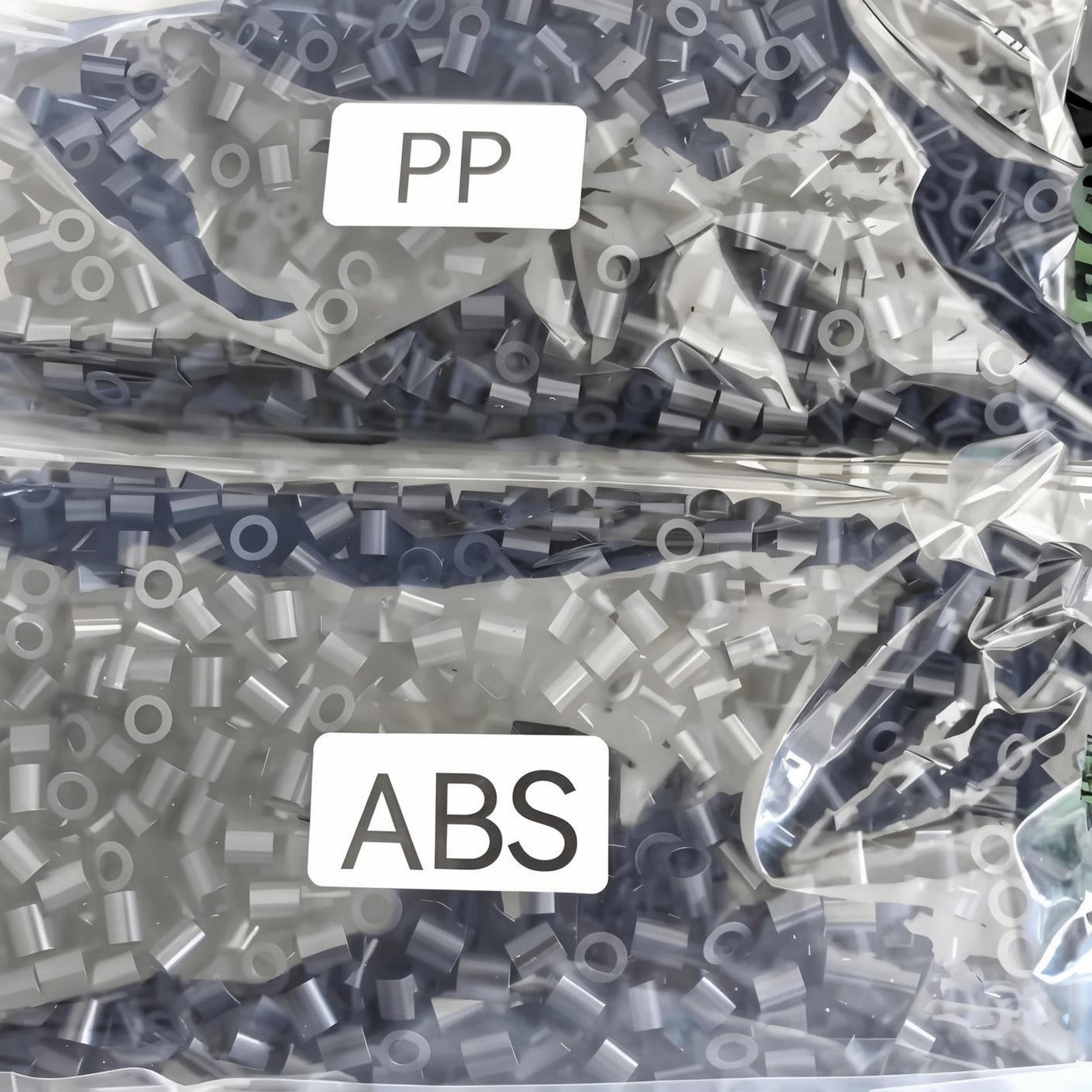

Supported Materials: ABS and PP

Most car door panels are made of ABS (Acrylonitrile Butadiene Styrene) or PP (Polypropylene). Both materials respond excellently to ultrasonic welding:

✔ Welding time: 1–3 seconds

✔ No screws or glue needed

✔ Clean, strong, and professional results

✔ Maintains panel structure and look

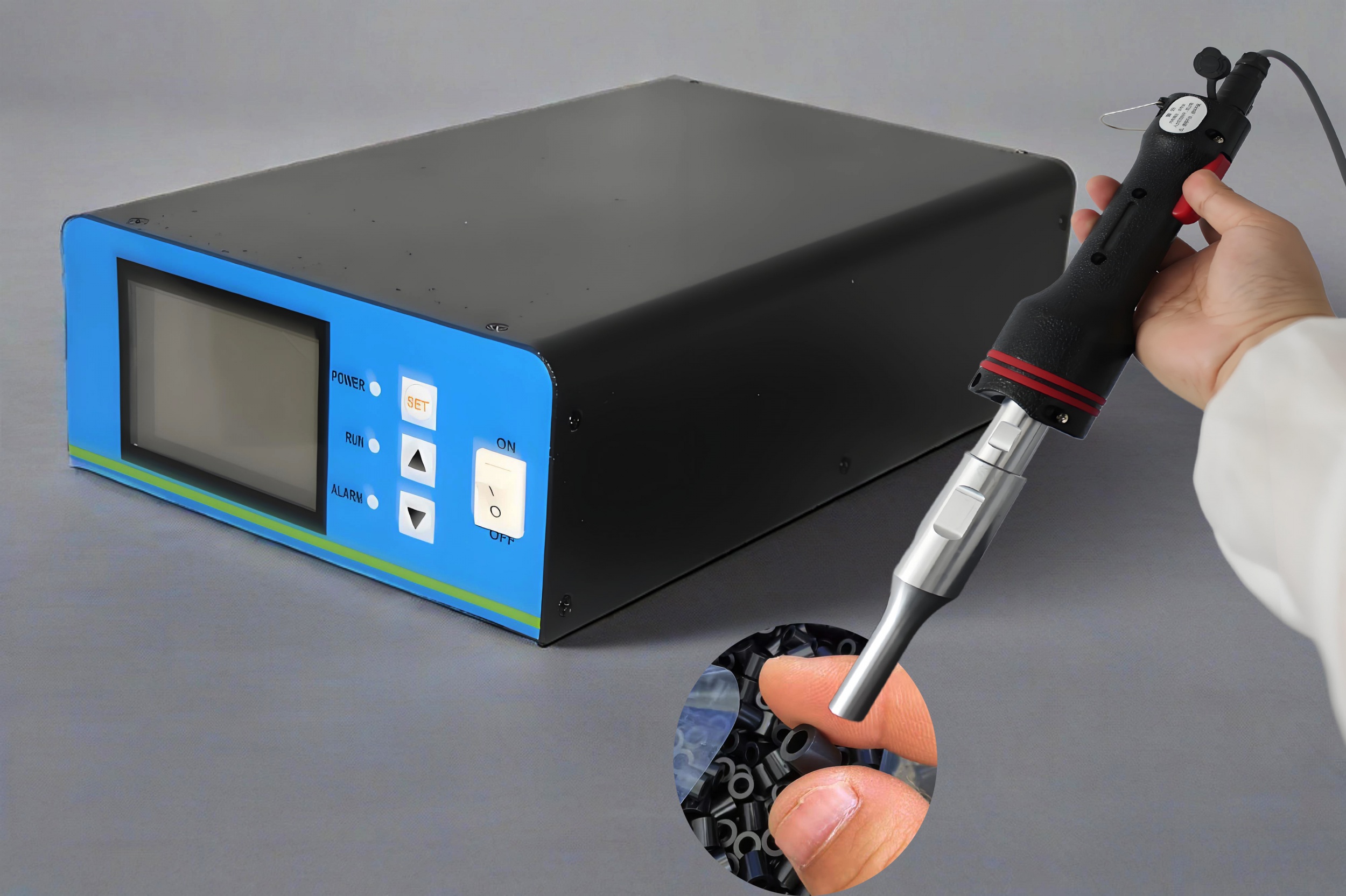

Easy Operation: Handheld Welding for Precise Results

As shown in the photos, the machine includes a digital control unit and a handheld ultrasonic welder. The operator simply:

- Aligns the tip to the desired welding point

- Activates the welding process (1–2 seconds)

- Lets it cool briefly — and it's done!

No preheating, no consumables, and perfect for workshops, car modification stores, and service centers.

Welded Finish = OEM Quality

The welding points after processing are smooth, clean, and tightly bonded. There are no visible gaps or damage, and the overall appearance is nearly indistinguishable from the original factory assembly.

Whether you're a professional modification technician, a repair specialist, or a passionate DIY enthusiast, this Ultrasonic Plastic Welding Machinehttp://www.qjmachinery.com.cn/en/ is a powerful tool to restore car door panels after upgrades — efficiently, cleanly, and professionally.

Compatible with ABS & PP materials

Fast 1-second welds

Factory-like finish with no visible damage

Functional and Decorative Welding

- Door panel trim-to-base welding

- Speaker grille and acoustic cover attachment

- Ambient light guides to trim piece welding

- Map pocket and armrest brackets fixing

- Window switch frames and bezel joining

User: Automobile interior modification industry

Advantages- No need for screws or glue, improving appearance and environmental friendliness

- High-strength welding, not easy to fall off

- Easy to operate, suitable for large quantities and customized modifications

- Can be used with tooling fixtures to achieve automated/semi-automated operation