Technical Analysis and Application of Plastic Corrugated Box Ultrasonic Welding Machine

Technical Analysis and Application of Plastic Corrugated Box Ultrasonic Welding Machine

Blog Article

Introduction

In the modern logistics and packaging industry, plastic corrugated boxes are widely used due to their lightweight, sturdy, and durable characteristics. As the industry demands higher packaging efficiency and environmental standards, traditional welding methods can no longer meet these needs. Ultrasonic welding technology has emerged as a high-efficiency, environmentally friendly solution, becoming the mainstream technology for welding plastic corrugated boxes. This article will provide a detailed introduction to the technical principles, key components, application cases, and future development directions of the plastic corrugated box ultrasonic welding machine.

Technical Principles

Ultrasonic welding utilizes high-frequency mechanical vibration energy. A transducer converts electrical energy into high-frequency mechanical vibration, and a welding head transfers this vibrational energy to the contact surfaces of the plastic workpieces. The high-frequency vibration generates intense friction at the contact surfaces, causing the plastic surfaces to melt and rapidly solidify, resulting in a strong weld. This process does not require any adhesives or solvents, making the welding process quick and environmentally friendly.

Key Components

- Ultrasonic Generator: Generates high-frequency electrical energy, typically ranging from 20kHz to 40kHz.

- Transducer: Converts high-frequency electrical energy into mechanical vibrational energy.

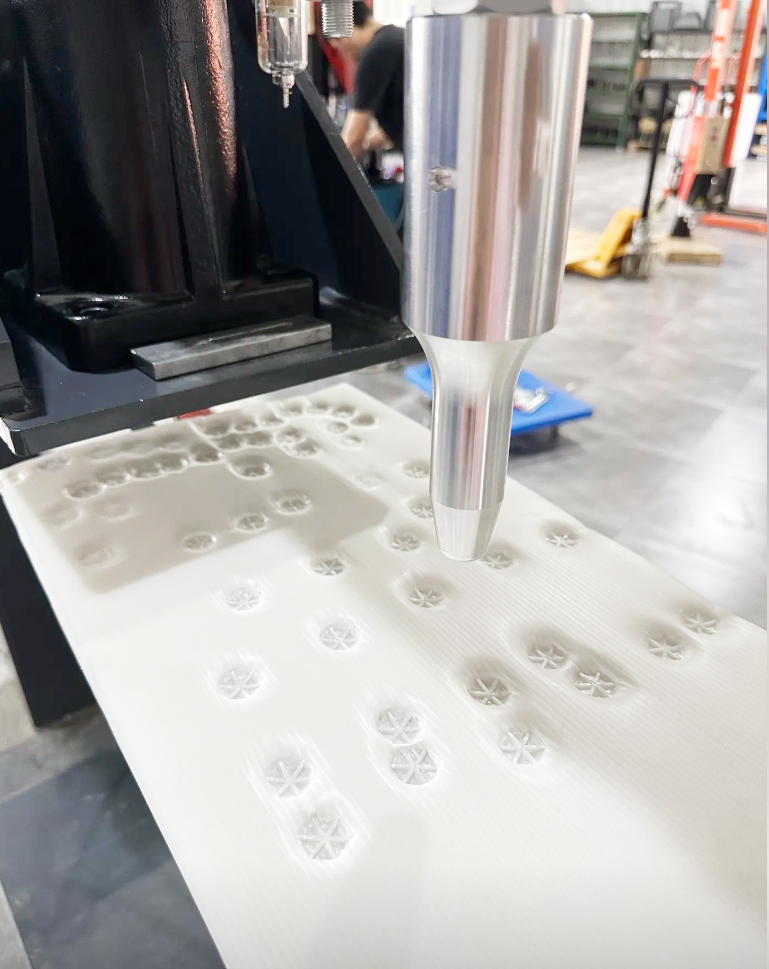

- Welding Head (Sonotrode): Transfers mechanical vibrational energy to the workpiece surface, concentrating energy for welding.

- Pressure Device: Provides the necessary pressure during welding to ensure weld quality.

- Control System: Adjusts and monitors welding parameters (such as vibration frequency, welding time, pressure) to ensure stability and consistency in each weld.

Technical Features

- High Efficiency and Energy Saving: Ultrasonic welding does not require preheating, has a short welding time, and consumes less energy. It reduces energy consumption by over 30% compared to traditional welding methods.

- Environmentally Friendly and Safe: The welding process produces no smoke or dust and emits no harmful substances, fully complying with environmental standards. The lower welding temperature also reduces safety hazards associated with high-temperature welding.

- Precision and Reliability: Digital control systems allow precise adjustment of welding parameters, ensuring the consistency and strength of each weld.

- Ease of Operation: The equipment features a user-friendly design with an intuitive interface, making it easy for workers to operate without extensive training.

- Convenient Maintenance: The modular design facilitates easy disassembly and maintenance, reducing downtime and maintenance costs.

Application Case

A large logistics company significantly improved its packaging efficiency after introducing the qijiang plastic corrugated box ultrasonic welding machine. The machine's high-efficiency welding capability allows for the welding of 300 plastic corrugated boxes per hour, a 40% increase over traditional hot melt welding methods. Additionally, the pollution-free welding process greatly improved the factory environment, meeting stringent environmental requirements. The company’s manager reported that the ultrasonic welding machine not only enhanced production efficiency but also significantly improved product quality and customer satisfaction.

Future Development

With continuous technological advancements and expanding application fields, ultrasonic welding technology is poised for broader future prospects. Future development directions include:

- Intelligent and Automated Systems: Incorporating more intelligent control and automation technologies to achieve fully automated production, further enhancing production efficiency and product quality.

- Multifunctional Capabilities: Developing ultrasonic welding equipment suitable for a wider range of materials and structures to meet diverse industry needs.

- Green and Sustainable Development: Further reducing energy consumption and pollutant emissions to promote greener and more sustainable welding technology.

- Innovative Material Applications: As new plastic materials continue to emerge, ultrasonic welding technology will be continually optimized to meet the welding requirements of more innovative materials.

Conclusion

The plastic corrugated box ultrasonic welding machine, as a high-efficiency, environmentally friendly welding solution, perfectly meets the needs of modern industry for high-quality and high-efficiency production. Its high efficiency, environmental friendliness, precision, and ease of use make it widely applicable in the logistics and packaging industry. With continuous technological innovation and development, ultrasonic welding technology will play a vital role in more fields, bringing significant economic and social benefits to the indust/http://www.qjmachinery.com.cn/en/ Report this page