Technical Principles and Applications of Ultrasonic Welding of Enameled Copper Wire

Technical Principles and Applications of Ultrasonic Welding of Enameled Copper Wire

Blog Article

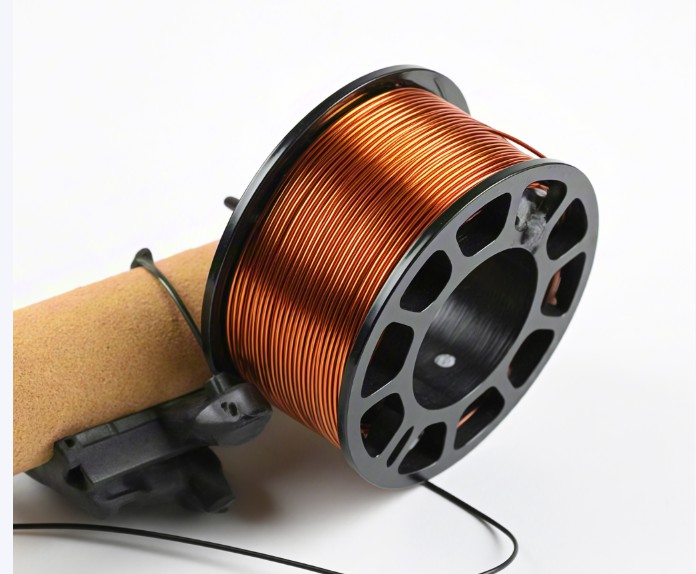

Enameled copper wire is widely used in motors, transformers, electronic coils, and inductive components, with an insulating varnish coating on its surface. Traditional welding methods, such as soldering or resistance welding, Ultrasonic welding technology enables efficient and reliable welding , significantly improving production efficiency and connection quality.

This article explores the working principles, process flow, influencing factors, and applications of ultrasonic welding of enameled copper wire.

Principle of Ultrasonic Welding enameled copper wire.

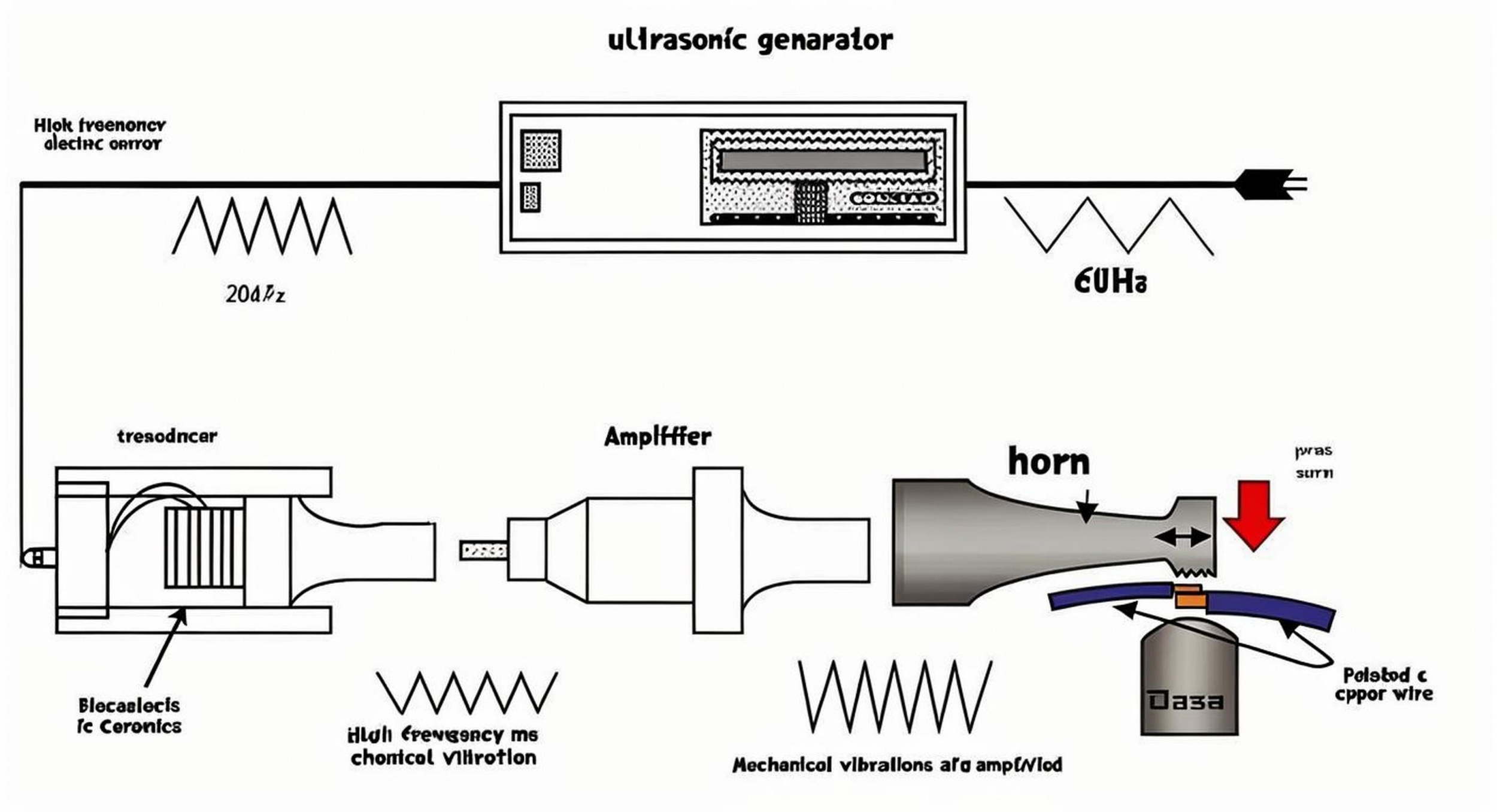

Ultrasonic welding is a solid-state welding technique that applies high-frequency mechanical vibrations 20kHz to the workpieces, causing friction at the contact area and forming a robust metallic bond under pressure.

Ultrasonic Vibration: The transducer converts electrical energy into high-frequency mechanical vibrations, which are amplified and transmitted to the enameled copper wire contact area via the booster and welding horn.

Friction Removal of Varnish Layer: The high-frequency friction energy generated by ultrasonic vibrations directly removes the insulating varnish layer on the copper wire surface, exposing the copper material and allowing direct metal-to-metal contact.

Metal Plastic Deformation and Welding: Continued ultrasonic vibration generates localized heat and softens the contact metal surfaces, allowing molecular diffusion and reorganization, forming a strong metallurgical bond.

Cooling and Forming: After stopping ultrasonic vibrations, the welded area cools rapidly, creating a stable connection.

How to operation of Ultrasonic Welding of Enameled Copper Wire

Major steps:

1.Material Preparation: Select suitable enameled copper wire (diameter range generally 0.1mm-1.5mm) and ensure the wire is clean and free of contamination.

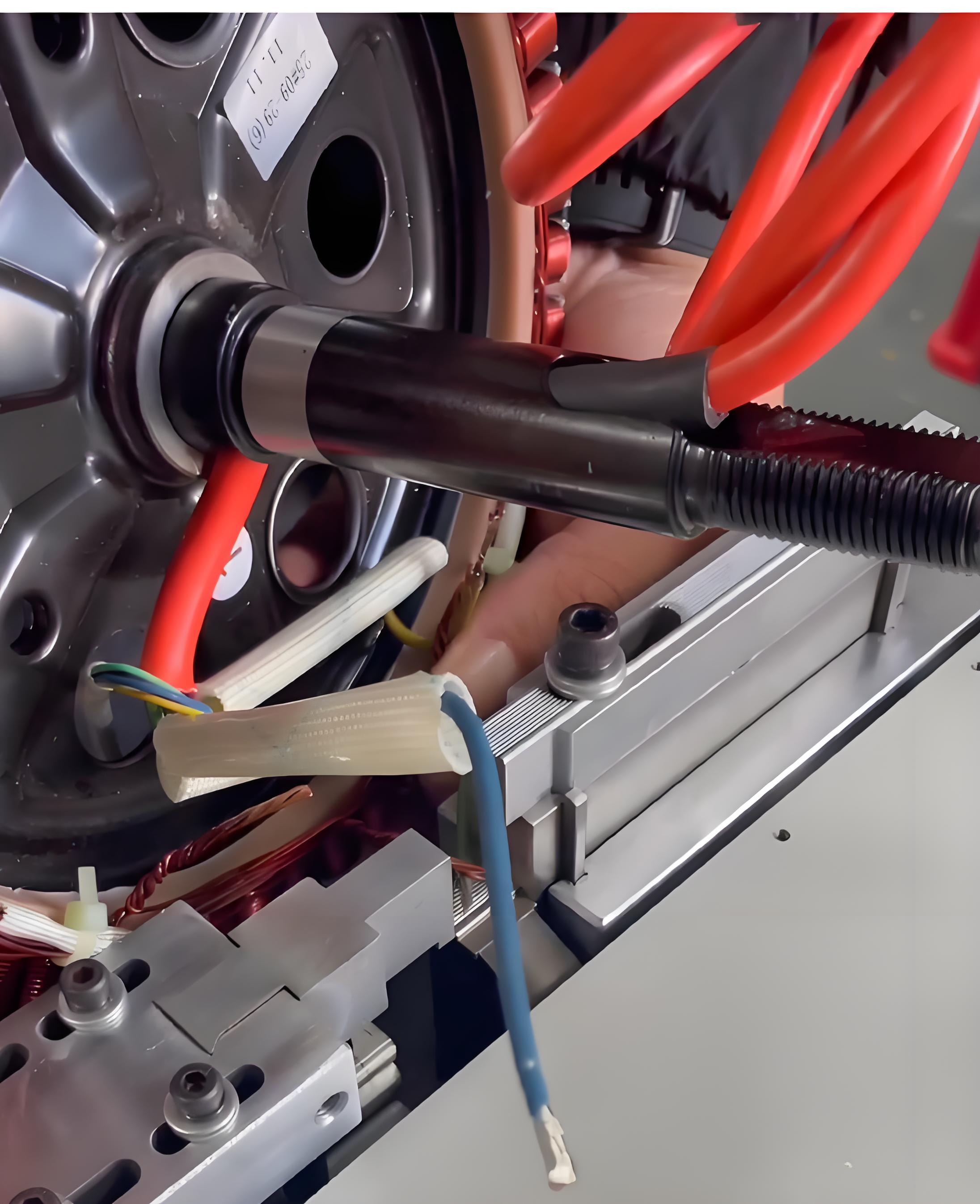

2.Fixture Fixation: Place the enameled wire in the welding fixture, ensuring a proper arrangement (parallel or stacked alignment).

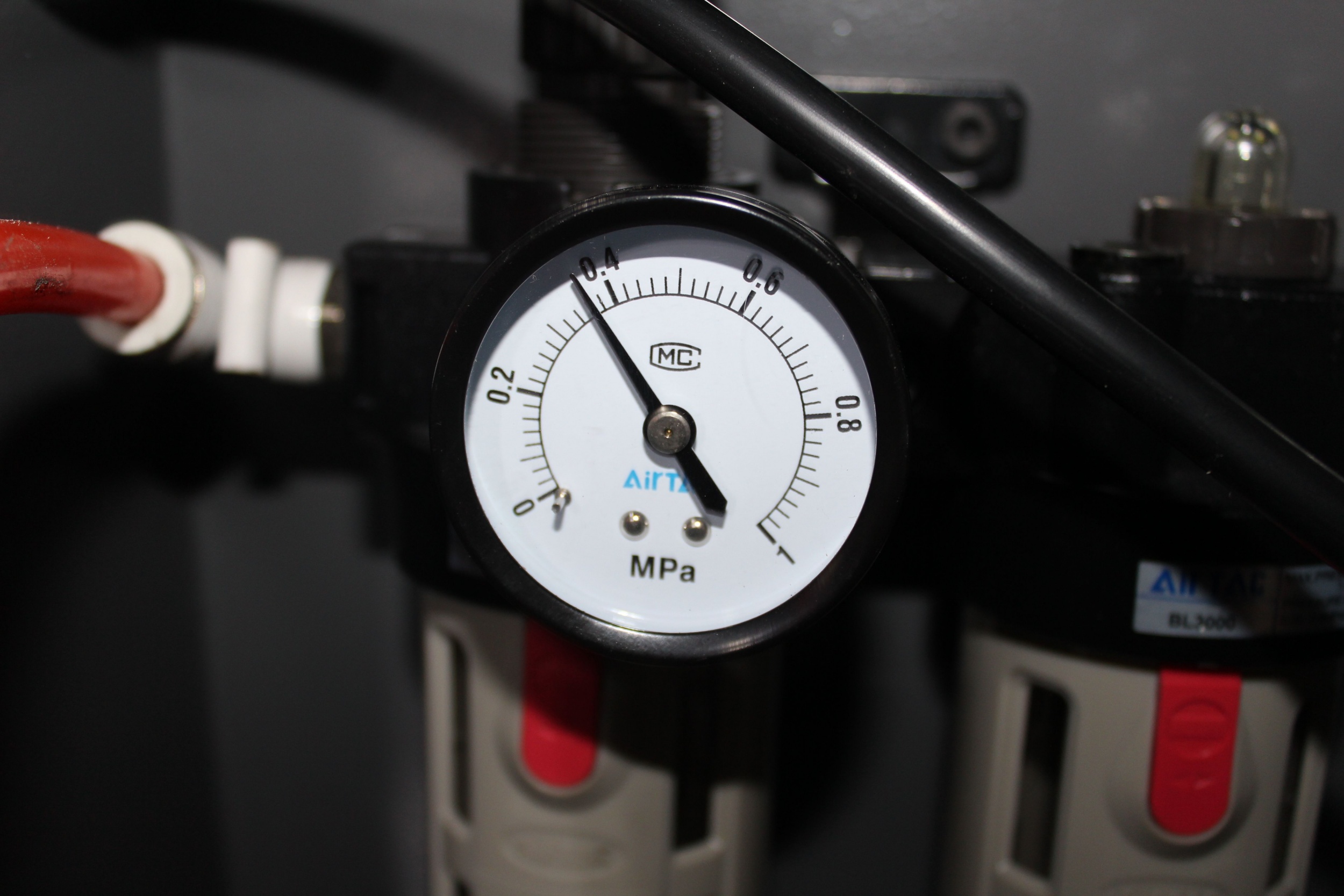

3.Parameter Adjustment: Set the ultrasonic welding machine parameters, such as amplitude, welding pressure, and welding time.

Welding Execution: Start the ultrasonic welding system, where the welding horn applies high-frequency vibration and pressure for welding.

4.Quality Inspection: Check the strength, conductivity, and consistency of the weld joint.

Key Factors Affecting Welding Quality

01.Welding Parameters

Amplitude: Determines varnish removal and welding quality, typically ranging from 20μm~50μm.

Welding Pressure: Excessive pressure may break the wire, while insufficient pressure leads to weak welding.

Welding Time: Must be adjusted based on wire diameter and material, usually between 100ms~1000ms.

02 Wire Characteristics

Copper Wire Diameter: Smaller-diameter enameled wires are more sensitive to ultrasonic vibrations and require precise parameter control.

Varnish Thickness and Composition: Different insulating varnishes (e.g., polyimide, polyester) affect the welding results differently.

03.Welding Tooling and Horn Design

Horn Shape: Must be designed according to the wire shape to ensure uniform pressure distribution.

Fixture Design: Should provide good fixation to prevent displacement during welding.

Advantages

Low Heat Input, preventing damage to the wire and its insulation.

Stable Welding Quality, providing high connection strength, low resistance, and reliability.

Environmentally Friendly, eliminating the need for solder or chemical cleaning agents.

Application Fields

Ultrasonic welding of enameled copper wire is widely used in:

Motors and Transformers: Coil winding welding to enhance motor reliability.

New Energy Vehicles: Copper wire connections in battery management systems (BMS).

Electronic Components: Inductor coils, micro-sensors, and other component welding.

Aerospace Industry: High-reliability harness connections.

Ultrasonic welding of enameled copper wire is an efficient, environmentally friendly, and reliable welding technique with broad applications in multiple industries. By optimizing welding parameters and designing suitable welding horns and fixtures, welding quality and production efficiency can be further improved. In the future, with the advancement of automation technology, ultrasonic welding will play a more significant role in precision manufacturing.

Keywords: Ultrasonic welding, enameled copper wire, welding process, electronics manufacturinghttp://www.qjmachinery.com.cn/en/Ultrasonic-Metal-Copper-Wire-welding-Machine-PG6963692http://www.qjmachinery.com.cn/en/Ultrasonic-Metal-Copper-Wire-welding-Machine-PG6963692http://www.qjmachinery.com.cn/en/Ultrasonic-Metal-Copper-Wire-welding-Machine-PG6963692http://www.qjmachinery.com.cn/en/Ultrasonic-Metal-Copper-Wire-welding-Machine-PG6963692http://www.qjmachinery.com.cn/en/Ultrasonic-Metal-Copper-Wire-welding-Machine-PG6963692http://www.qjmachinery.com.cn/en/Ultrasonic-Metal-Copper-Wire-welding-Machine-PG6963692